OUR RESEARCH INTERESTS

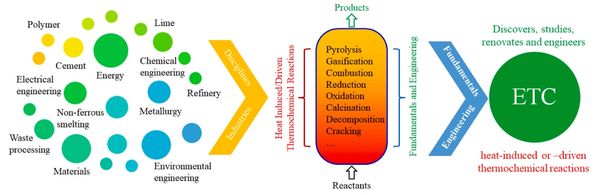

Coal-fred power plants, residential and industrial coal-fred boilers, iron and steel manufacturing, non-ferrous metallurgical processes, cement production, and lime production, contribute to over 40% of global carbon dioxide emissions. These industrial processes are crucial in producing energy and materials essential for economic and social development. Therefore, to effectively reduce carbon dioxide emissions and expedite progress toward carbonneutrality, it is imperative to prioritize technological innovation in these high-emission processes. These processes encompass various industries but share a common characteristic: they all involve thermochemical reactions, such as pyrolysis, gasifcation, combustion, decomposition, oxidation, and reduction. Despite the different attributes, these thermochemical reactions share a common inherent feature: they are driven or induced by heat and are operated at high temperatures. This commonality underscores the importance of a newly emerging science and technology known as Engineering Thermochemistry, which is critical in guiding our efforts to address carbon emissions.

Focusing specifcally on heat-induced/-driven thermochemical reactions, ETC refnes and resolves their common scientifc fundamentals and engineering issues, thereby promoting the discovery, research, innovation, and engineering of thermochemical reactions in a scientifc and systematic approach.

ETC is initially proposed to link and integrate the fundamental research and engineering of thermochemical reactions in different disciplines and industries. After several years of development, it has emerged as a new scientifc discipline and connotes more specialization of scientifc signifcance. It discerns and integrates a common set of core metaphors and concepts in the feld of fundamental research and engineering technologies of thermochemical reactions that used to be dealt with separately or independently in different scientifc disciplines and practiced in different industrial sectors.

Essentially, ETC investigates characteristic thermochemical reactions and their interacting reaction network for scientifc fundamentals (e.g., chemistry and physics) and engineering techniques concerning a specifc reaction or reaction process. With the target of engineering a reaction, the investigation has to be at different scales covering micro (or particles), reactor, and process. Special emphasis should be placed on optimizing the interactive matching between heating and reactions.

Statistical analysis indicates that excessive carbon emissions are from several superemiters, including boilers and motors burning fossil fuels (i.e. coal, oil and natural gas) for the generation of power or driving force, industrial combustion for heat and steam generation, electrolytic and electric-arc furnaces for ultrahigh-temperature mineral-processing or metallurgical processes (calcium carbide, silicon, fused magnesia, etc.) and hightemperature kilns for the production of cement, lime and refractory materials. These super-emiters emit over 50% of global CO2 emissions. Reducing CO2 from these super-emiters effectively curbs and neutralizes carbon emissions andmust be the top priority. We have realized that almost all of the aforementioned CO2 super-emiters involve heat-induced or heat-driven thermochemical reactions, such as combustion, gasifcation, decomposition, calcination, reduction and sinteringTreating thermochemical reactions with a more systematic and disciplined approach, ETC can lead to scientifc breakthroughs and technological innovations toward carbon neutrality through the pathways of reduction, substitution and recycling of carbon.